Seven advantages of hydraulic rope compensation installations

Despite its great safety and cost advantages, hydraulic rope compensation is one of the most commonly overlooked aids for lifts and other conveyance systems.

When it comes to classic rope drives, adjusting them to ensure the load distribution to each rope is balanced during operation is almost impossible. Even when using devices to measure individual rope tension, proper compensation can only be achieved here at one position of the car.

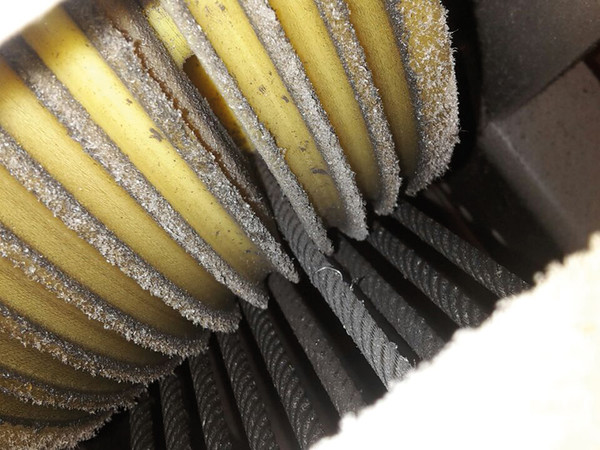

The consequence of uneven rope tensions in the face of growing divergence is then the loss of the high set safety factors for the steel rope. This imbalance then makes itself noticeable in the load distribution of the rope and as a result of the slippage cause wear on ropes, traction sheave and deflection pulleys. Due to the increasingly embedded rope, the wear increases exponentially and can result in early failure and renewal of the lifting gear.

Uneven tension distribution considerably impairs the performance and service life of the ropes.

The seven most important advantages of hydraulic rope compensation systems:

1. Considerably lower maintenance costs:

Unevenly distributed rope tension results in different loading. More heavily loaded ropes wear out much faster. To prevent this, the rope tension must be subjected to regular maintenance, monitored and adjusted. Hydraulic rope compensation systems help to lower maintenance costs. Usually, no routine or preventive maintenance is required and the intervals are thereby exponentially extended.

System on 1:1 system (13 ropes). Photo: © Vertima

System on 1:1 system (13 ropes). Photo: © Vertima2. Manual measurements and measurement logs unnecessary:

In the past, measuring rope tension in lift systems was difficult. One of commonest methods is still finger testing of the tension. Obviously, this is not the ideal procedure. Technical planners are increasingly demanding submission of logs on the measurement of rope tension after installation. By contrast, hydraulic rope compensation systems offer permanent, efficient rope compensation in real time with perfect precision.

3. Enhanced safety:

When calculating rope safety, the number of ropes required to guarantee adequate safety in accordance with the legal requirements is determined. All ropes (as calculated) must be equally tensioned for safe use. However, this can only be guaranteed by measurements at the time of measurement. Hydraulic rope compensation automatically ensures here that every rope, as specified in the safety calculation, permanently and automatically transfers the same force.

4. Fast and easy installation:

Hydraulic rope compensation systems are easy to install. They can be installed in almost every position or location to cope with almost all special requirements and circumstances in all kinds of lift systems and buildings (including overhead installation).

Worn SR furrow. Photo: © Vertima

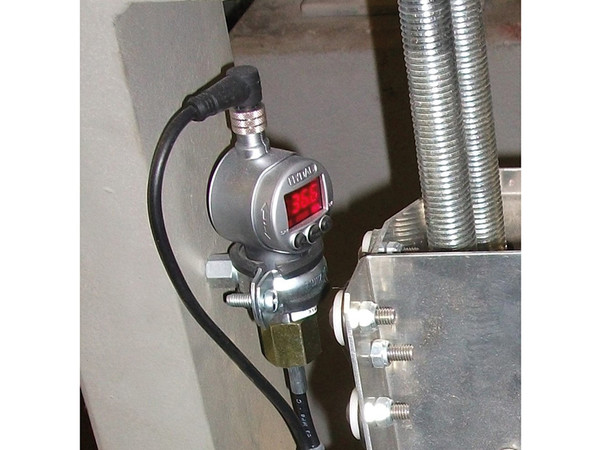

Worn SR furrow. Photo: © Vertima5. Precise, easy load measurement can be integrated:

Pressure is generated via the load on the ropes in the hydraulic rope compensation systems. Since the effective pressure surfaces are known to the system manufacturers, what load is suspended on the ropes at what pressure emerges automatically. By connecting a pressure switch (digital) or a pressure sensor (analogue), pure overload determination or precise load measurement (absolute, without test weights) can as a result be performed in a simple manner.

6. Increased rope service life:

Considerable extension of the rope service life is possible by using an automatic system to compensate for differing rope tensions. This saves high costs, since the period of time between the costly individual rope, pulley sheave and traction sheave replacements is drastically extended. In fact, studies show that by reducing the differences in rope tensions, the service life of the ropes is extended by almost 50 percent. The systems automatically compensate rope stretching and can, e.g. via slack rope switches, give advance warning in good time if one or more ropes has become stretched too much.

Load measurement with pressure sensor. Photo: © Vertima

Load measurement with pressure sensor. Photo: © Vertima7. Improved travel comfort and system performance:

One of the biggest advantages is the ability to offer lift users a smoother trip. Since the rope compensation systems reduce the slippage of the ropes across the traction sheave and pulley sheaves, there is a noticeable reduction in annoying vibrations and noises for lift users. In addition, rope compensation systems improve the precision of the lift. Since there is practically no more movement via steel or rubber springs, the stopping precision of the lift is noticeably better. This results in greater safety for lift users.

Conclusion:

When switching from a conventional rope attachment to a system with hydraulic compensation, one quickly notices how its deployment increases efficiency and performance and cuts operating costs. Consequently, the installation of hydraulic rope compensation can be of great benefit to many companies and their customers.

By Markus Stucke

The author is the managing director of Vertima.

More information: vertima.de

Write a comment