Occupational safety in the digitalisation era

Digital, software-based safety functions are increasingly replacing or supplementing mechanical protective installations in systems subject to monitoring, such as lifts.

This entails risks that can affect the occupational safety of inspectors and fitters. TÜV Süd shows you how these can be reduced.

Programmable safety functions are more economic in operation and maintenance compared to safety components such as mechanical safety gear triggers or circuit breakers. Other advantages are that function-generating software does not wear out or corrode and can in addition be networked. This facilitates remote maintenance, status monitoring and predictive maintenance.

The disadvantage of software solutions compared to physical components is that safety circuits are more difficult to understand and inspect. Does the protective installation actually exist? Is it not only functional, but working as intended? To find out, the inspectors have to trigger the entire safety chain or draw on system-independent measuring systems - relying on the "green light" of the controller that everything is working is not enough.

Inspection and maintenance of lifts

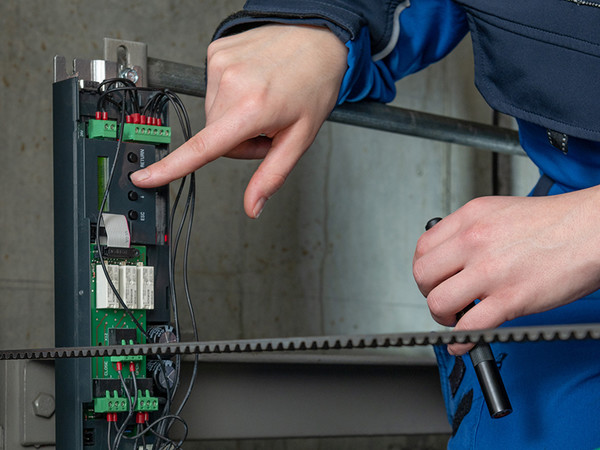

Photo: © TÜV Süd

Photo: © TÜV SüdMany modern lifts are fitted with electronic shaft copying. Among other things, this means that the position of the landing doors and all switches is recorded in the programmable controller through corresponding parameters. A software update can unintentionally restore these to the factory settings.

Consequently, the shaft position of the software-based inspection limit switch can be confused with that of the mechanical limit switch. The risk then exists on the occasion of a recurrent inspection that the expert can be trapped in the car or on the car roof - this also applies to fitters during maintenance. Before the recurrent inspection and maintenance, you should make sure that the lift parameters have been correctly recorded or check the software status.

Other dangers are being crushed in or even falling down the lift shaft. An electronic safety function frequently monitors that the car does not move unintentionally when the doors are opened (UCMP – Unintended Car Movement Prevention). This safety function does not trigger any brake if the mechanical equipment is worn out. Electronic controllers have a self-diagnosis function, but they do not record any physical defects in triggering control elements.

Inspection equipment and methods

The experts at TÜV Süd conduct their inspections according to the technical rules for operational safety of lifts (TRBS 1201-4), among other things, and in doing so take into account the increasing relevance of functional safety and in future also of IT security.

What is above all important in determining and evaluating the effectiveness of PESSRAL (programmable electronic systems in safety-related applications for lifts) by triggering the safety circuit and checking the CRC code is whether the software version in place is qualified and approved for the hardware configuration.

Assistance systems like the TÜV Süd inspection app facilitate inspection on the spot. It guides the expert through the inspection and helps him with routine tasks, such as documentation. Moreover, the operator gets his report at the "press of a button" and can as a result save time.

Electronic lift measurement procedure

Photo: © TÜV Süd

Photo: © TÜV SüdAnother system is the electronic lift measurement procedure "Adiasystem" from TÜV Süd. This allows you to check the effectiveness of the lift’s traction capacity and safety gear. An intelligent non-invasive measurement system with electronic sensors records and calculates safety-relevant key data directly to the lift.

The system is suitable for all traction sheave and hydraulic lifts and replaces time and cost-intensive load tests. This extends not just the service life of important components, but also shortens the downtime of the lift.

By Dr Rolf Zöllner

The author is the Head of Business Development in the Conveyance Technology Department, TÜV Süd Industrie Service GmbH

More information: tuvsud.com/aufzuege

Write a comment