KWeb: digital added value for all concerned

KW Aufzugstechnik has for some time now been fitting its controllers as standard with gateways and an LTE network connection.

The goal is to create added digital value for assembly and service companies, facility management and operators via the cloud monitoring service KWeb. This has created a kind of community, which continually improves and individualises KWeb.

Digital transformation is making advances in many industries, enhancing data availability and as a result, customers’ expectations. For example, large properties are no longer sold with LED luminaires, but with light – round the clock. Investors are also demanding ever greater cost efficiency and improved availability.

Availability

Photo: © KW Aufzugstechnik

Photo: © KW Aufzugstechnik The challenge of the future will be in the availability of lifts and the economic implementation of service performance. This is the task of installers and service providers; operators want availability of over 99 percent.

How businesses implement this requirement in practice is up to them – whether with frequent visits to the lift or an intelligent, cloud-based monitoring and maintenance strategy.

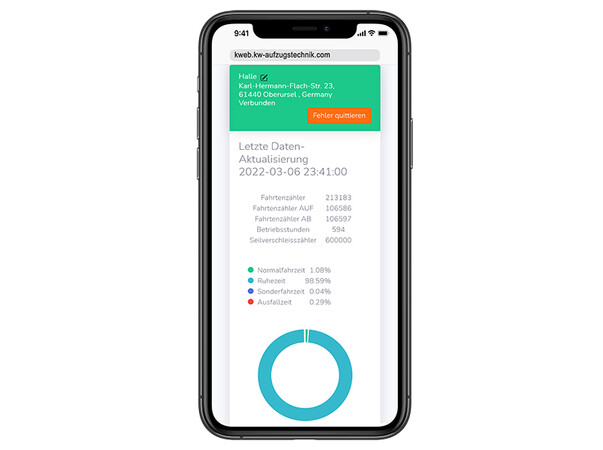

With the help of an Internet-capable device, KWeb can remotely

• see – by visualising the car status and travel and door movements

• influence – by assigning internal and external calls and blocking floors

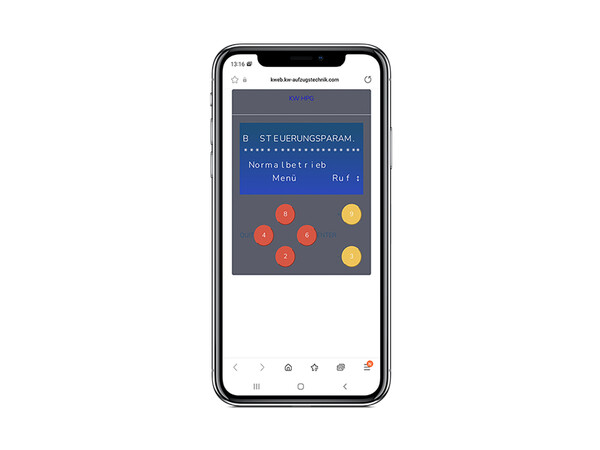

• understand – through a virtual diagnosis terminal for changing and optimising settings

• advise – when deciding on the maintenance time in relation to belt or rope wear and running properties of the landing and car doors.

The electronic lift attendant function supports the operator in regular functional checks of the lift and its documentation. The special feature of KWeb: thanks to 4G/5G network capability, updates are transmitted ‘over-the-air’ to the controller. Consequently, the David 613 controllers are among the few controller systems which automatically improve during their service life and can adjust to new statutory standards.

One-Stop – One-Solution Strategy

Photo: © KW Aufzugstechnik

Photo: © KW Aufzugstechnik When planning a malfunction or repair deployment, knowing the status or problems of the lift in advance is very helpful. The controller error memory shows which errors occurred where and when – this also includes shaft information and travel curve information. The situation-related data of the controller are likewise filed.

As support, the lift database of the KWeb supplies over 100 data points of the components connected, their technical data and the settings of the lift affected. This simplifies selecting the right material and service technician with corresponding qualifications. On site, the fitter is shown the location of the key safe, main entrance and location of the lift via the displayed building floor plan. In the event of doubt, a remote support team provides assistance.

Game Changer

As a result, assembly and maintenance companies can expand the radius of their business activity, since this is no longer restricted by the number of fitters and their range. Lifts that are distant or have access restrictions can be repaired and maintained just as well as lifts that are around the corner.

Consequently, the technology of KWeb, which maps lifts completely in the world wide web, can become a game changer for individual business operations as well as for the entire lift environment. The classic cost structure in lift maintenance and troubleshooting is changing.

But the other parties, such as authorised inspection bodies, facility management and lift operators, will in future also demand and get more information about lifts. KWeb provides data evaluations for this purpose, which can be exported in all kinds of formats.

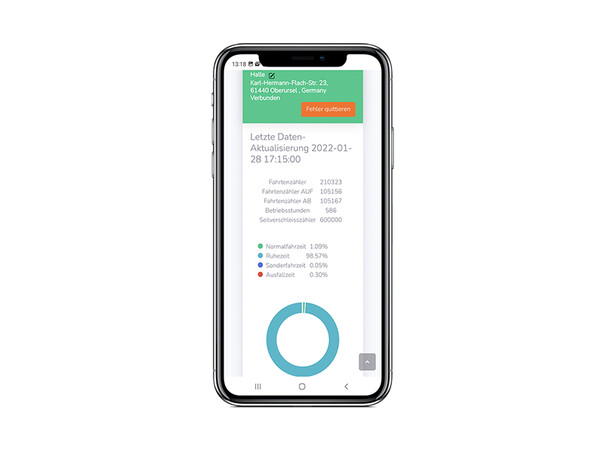

Security

Photo: © KW Aufzugstechnik

Photo: © KW Aufzugstechnik The question hovering over all of this, of course, is how secure the entire system is. "We decided on highly secure encryption, where the communication between cloud monitoring and customer lifts can only occur via the KWeb server, which is located in a German data centre," emphasised Hans-Werner Walbert, managing director of KW Aufzugstechnik.

The registered user only has access to the functions for which it was authorised. The web page of the cloud monitoring is protected by a content security policy against manipulation: for example, special security cookies protect against falsification of commands.

More information: kw-aufzugstechnik.de

Write a comment