IoT facilitates an efficiency leap for the lift world

Lifts are predestined for IoT (Internet of Things) applications. This is why the Cedes Group is developing a new portfolio of sensors.

By Christian-Erik Thöny

IoT permits a completely new dimension of connectivity in all kinds of industrial applications and products. This is based on the data collected by a constantly increasing number of sensors installed of every variety. The result is a "raw material" whose availability, unlike oil, is inexhaustible.

The international weekly, "The Economist", actually declared data to be the oil of the 21st century: it was the most valuable resource today. However, data have to be refined just like oil. Artificial intelligence plays a decisive role here. Data only become strong and usable once they are linked in peripheral systems, such as additional lifts, escalators, building controls, air conditioning or automatic doors.

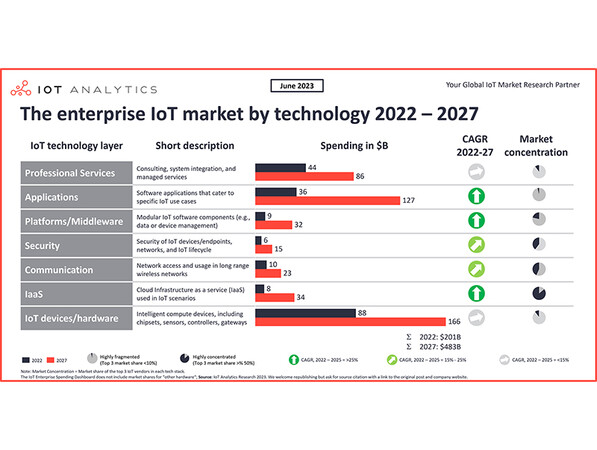

As a result, IoT has developed into an enormous industry with very high growth rates. The worldwide turnover is expected to grow in just five years from 201 billion dollars in 2022 to 483 billion dollars in 2027.

New product portfolio

Photo: © IoT Analytics

Photo: © IoT AnalyticsLifts are predestined for IoT applications since they have a high degree of standardisation and due to urbanisation and demographic development represent an increasingly important vertical means of transport.

The Cedes Group has accepted this challenge and developed a new sensor product portfolio ("Fusion"), which has the ability to communicate with higher clouds and as a result makes IoT in the lift sector possible in the first place.

Metaphorically, these new Cedes sensors are not just able to "see" (through the light curtain") but also acquire additional "senses" such as "acceleration", "pressure", "temperature" and "humidity". This permits the evaluation and monitoring of the function and status of the lift in its ambient environment. The operating status analysis is completed through combination with the operating data of the drive elements such as motors and controllers. The passenger flows are recorded and the operator of the lift or lift cluster obtains valuable information on how the lift is used.

AI-supported features analyses

However, AI-supported evaluations are even more important for service. It will be possible to determine or predict fairly accurately which components are going to be in a negative trend and will fail in a particular period. Based on this comprehensive number of status data with AI-supported feature analyses, the ability to make highly accurate forecasts is easy to imagine.

The prospect of enhancing the quality of service and making it more efficient, faster – i.e. more economic – is fascinating. As if this were not enough, it will permit monitoring the quality of the service work itself. Service can be performed by a wider group since thanks to the comprehensive information above, the service deployment is simplified.

Partnership with relayr

Photo: © IoT Analytics

Photo: © IoT AnalyticsThe AI-"refined" status data of the Cedes "Fusion" sensor are sent to the cloud by the communication capable system. The data are prepared in combination with AI in the cloud and linked to additional lifts and other relevant systems. As a result, a "common operating picture" (COP) arises, which provides a comprehensive description of the lift or lift cluster in its actual environment. This cloud system is operated by the "Skyler Elevate" system of the experienced company relayr (in partnership with the Cedes sensor systems).

Currently, it is becoming increasingly clear that all kinds of interest groups related to lifts and escalators want to have the operating data. Sooner or later, these will have to be provided at least in part by the manufacturers and service companies. This will happen – whether we want it or not, with us or without us.

The state procures the data

The state of Singapore is a pioneer, a role model, so to speak. Data from all areas of life are recorded, prepared and provided in a data platform to all interest groups as DaaS (Data as a Service). This enables all app developers and operators to access these data and provide their SW services, SaaS (SW as a Service) to the public.

In Singapore, the focus is on the vertical transport in particular, i.e. the lifts. Since the lift OEMs do not provide the data, the state of Singapore has installed parallel non-invasive sensor systems in the shafts and procures the data itself. The service quality and costs are naturally monitored as a result.

The author was until recently CEO of the Cedes Group.

More information: cedes.com

Write a comment