Shortened construction times thanks to high performance construction lifts

The new Quartier Vienna Twentytwo is being erected by Signa and ARE within sight of Vienna’s St. Stephen’s Cathedral. Kone is installing the first of its second generation JumpLifts there.

By Oliver Züchner

Unlike the lifts of the first generation, developed for very high buildings, the new JumpLifts cover a very wide spectrum of buildings, ranging between nine and 48 floors. Like all JumpLifts, they cut construction times and costs and unburden logistics.

Originally, the general contractor for one of the two high-rise blocks of the new Quartier in Vienna Kagran wanted to use two conventional lifts without machine rooms as construction lifts. The time until the completion of the lifts was to be bridged by the usual exterior lifts.

"However, once the construction logistics experts determined that space for the construction lifts was absent and the schedule extremely tight, they pivoted to the new JumpLifts," explained Kone project manager Joachim Hahn. "In addition, this means the façade can be closed earlier and the interior finishing brought forward."

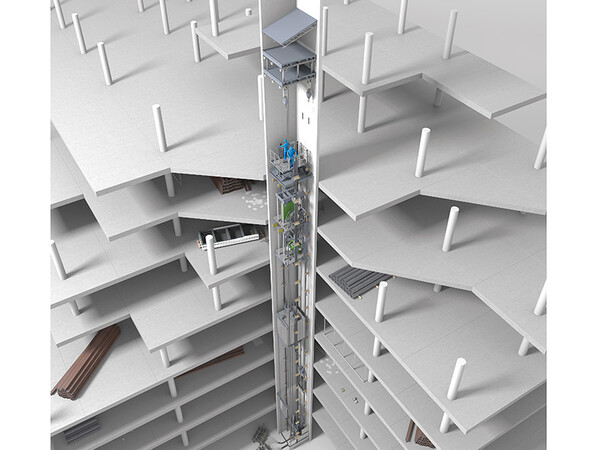

JumpLifts in operation in the shell construction phase

Photo: © Kone

Photo: © KoneShell construction of the eighth floor was completed at the end of June 2023. Installation of the JumpLift began. It will initially serve the levels from the ground floor to the fifth floor. Its drive will be installed on the guide rails while the controller and electrical systems will be attached to the shaft wall. A protective roof ("weather roof") will be installed on top.

As the building shell and along with it the lift shaft ascends higher, the drive, controller and electrical systems will be shifted upwards a few floors using a rope pulley. "In the first generation, all of the technology was mounted on a platform which was suspended at the top of the shaft and which was pulled upwards by a deck – the installation platform – mounted above it," Hahn recalled.

The "jumps" are repeated often enough until the building has reached its full height and the drive can be installed in its final position at the top in the shaft head.

Up to four tons payload

"When the building is in the construction shell stage, the lift is already fully mounted to a large extent. We just have to exchange a few components, like the rope suspension to turn the JumpLift into the final lift," the project manager pointed out.

Accordingly, the performance data of a JumpLift reach the values of the final installation or at least approach it: at 150 m maximum conveyance height, the cars can move up to four tons payload at a maximum of 4.0 m/s. Classic exterior lifts differ from these performance figures markedly – apart from the fact that they are dependent on the weather and much less comfortable.

Two JumpLifts were installed in Vienna

In Vienna Kone is installing the first of its second generation JumpLifts there. Photo: © Stefan Seelig

In Vienna Kone is installing the first of its second generation JumpLifts there. Photo: © Stefan SeeligThe number of JumpLifts in a building depends on the particular demands of the construction logistics as well as the number of jumps. In the case of the Vienna high-rise, a second JumpLift will be installed as soon as the shell has been completed up to the fourteenth floor.

This lift will then serve the floors up to the tenth floor. As a result, the construction logistics experts can deploy two lifts simultaneously to transport people and cargo. "Functional separation – personnel here, cargo there – is not planned in our case: each JumpLift transports everything and everyone," according to project manager Hahn.

Since two JumpLifts are available, the second is always available during the "jump breaks" of one lift. "Shifting the technology upwards along with lengthening the rope: this takes a week, during which one JumpLift handles the entire operation," he stated.

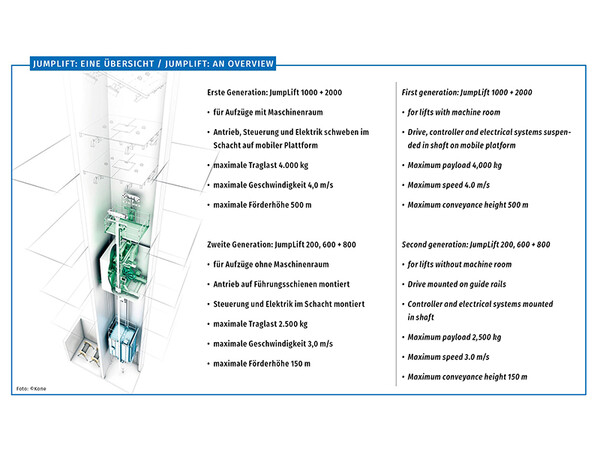

JumpLifts of the first and second generation

The JumpLift was originally designed for skyscrapers with high performance lifts with machine rooms. This is how iconic buildings like the "Turning Torso" in Malmö (completed 2006), "The Shard" (completed 2012) and "De Rotterdam" (completed 2013) arose. In Germany, the JumpLift was first used in 2021 in Frankfurt am Main in the office tower "ONE" and then in 2022 in "Edge East Side" at the Warsaw Bridge in Berlin.

At the end of 2022, Kone launched the second generation JumpLift worldwide. Economic use of it can already be made in buildings with nine or more floors – in places where lifts without machine rooms, like the Kone MonoSpace 500 and 700, would normally be used. This also means higher buildings are possible, as in the case of the Vienna Twentytwo. The high-rise there reached an impressive 47 floors.

Gain time with the JumpLift

Jumplift: An overview. Photo: © Kone

Jumplift: An overview. Photo: © KoneHow much time is gained by using a JumpLift actually depends on the building, the number of JumpLifts deployed and the other construction logistics. Kone estimates a reduction in several weeks in construction time for a nine-floor structure.

A 48-floor building could be finished months earlier, according to the company. Hence, given the shortage of personnel and soaring construction costs, the expense for using a JumpLift can definitely be worthwhile.

The author works for the communications agency MT-Medien.

More information: kone.de

Write a comment