Glass lift cladding

For the first time, the glass cladding of a lift tower was fitted with a GSP outer hull. This construction element was developed by iconic skin several years ago.

A 10 m high lift tower made of opaque black glass elements is a design highlight of the company headquarters of the office chair manufacturer Topstar in Langenneufnach. The glass cladding was realised with GSP, a construction element from iconic skin. The glass lift brings customers barrier-free directly into the factor sales area and is used as a communication surface for advertising messages.

Mounting of GSP is performed as when laying conventional sandwich panels, using a groove and tongue joint. As a result, the lift cladding is fast and easy to implement.

GSP advertising surface

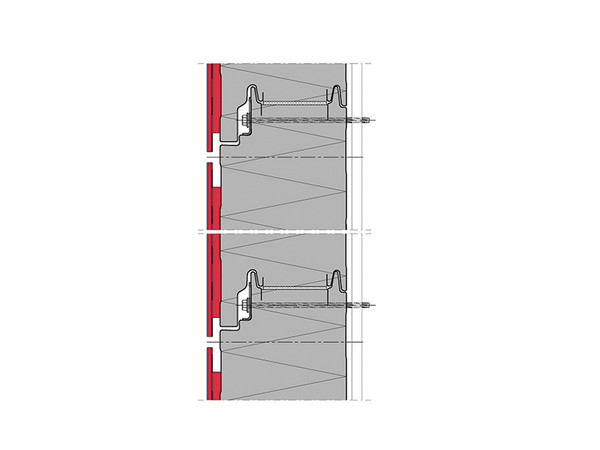

The individual GSP elements are screwed together on a substructure using a tongue and groove connection and mounted to fit precisely (Fig. shows a horizontal joint GSP PUR-H). Photo: © Iconic Skin

The individual GSP elements are screwed together on a substructure using a tongue and groove connection and mounted to fit precisely (Fig. shows a horizontal joint GSP PUR-H). Photo: © Iconic SkinFor the lift cladding, a version with minimal wall construction was chosen in the form of GSP PUR100-H. The approximately 114 mm thick element provides glass surface, wall and insulation in one product. GSP consists of a sandwich panel with polyurethane core wall and structurally bonded glass panes.

At Topstar, 19 GSP elements with lengths up to 3 m are laid horizontally on a steel substructure. By eliminating the need for mechanical attachment of the glass surface and concealing the screw connections, a frameless building envelope is created with even joint pattern, which Topstar uses as an advertising surface – a kind of glass screen.

Permanence with digital printing

Tongue-groove connection of two GSP elements. Photo: © iconic skin/BECKERLACOUR

Tongue-groove connection of two GSP elements. Photo: © iconic skin/BECKERLACOURIn line with the company CI, a black lift cladding was chosen. During the production process, the glass surface was given a black enamel surface through rotary printing. As a result, the GSP elements are weather-resistant, scratch- and light-proof as well as permanently bonded. Logos, graphics and lettering can also be applied permanently to GSP by digital printing.

In order to be able to replace advertising messages at changing intervals, Topstar dispensed with digital printing. Self-adhesive film was used to apply the current company slogan "Move your life!" Self-adhesive films have excellent bonding characteristics on glass surfaces and can be removed without leaving behind any residues, iconic skin emphasised.

More information:iconic-skin.com

GSP Glass Sandwich Panel: GSP is the first licensed façade element consisting of a serial sandwich panel with structurally bonded glass pane without mechanical attachment (abZ Z-10.4-674). GSP combines glass surface, wall and insulation in one construction element. GSP is optionally available with a core wall made of polyurethane (GSP PUR) or mineral wool (GSP MW). The glass surface can be individually designed and printed with ceramic paints to be weather-resistant, scratch- and light proof as well as permanently bonded. When used in combination with standard window and façade systems, GSP creates continuous glass sandwich facades. GSP provides U-values up to 0.13 W/(m²K) (GSP PUR200) in the opaque range without additional insulation.

Write a comment