The counterweight and energy efficiency

To enable lifts to be built and operated as efficiently as possible, the counterweight balancing should be designed with at least 40 percent. This leads to much lower energy consumption. Why is this?

By Ludwig Semmler

Lifts should be as durable and low-maintenance as possible as well as built and operated in an energetically efficient manner of course. To achieve these goals, considering the energy consumption of the lift just during the trip is insufficient.

Usually, energy efficiency is connected directly with energy feedback or energy storage. Depending on the building and capacity utilisation of the lift, the use of corresponding systems makes sense. Including these products in the consideration is not wrong but does not produce the greatest benefit. Instead, it makes far more sense to already examine the entire lift during the planning phase for energy-saving potential.

Long use and easy repair

Building energy-efficient lifts means putting lifts on the market that will be used for as long as possible. The supply of spare parts and the possibility of easy repair play an important role, possibly even the most important role.

The service life of these construction elements depends to a great extent on calculations of the traction sheave and rope. Apart from selecting the diameter of the rope, the traction sheave and the number of ropes, the selection of the counterweight balance also has a considerable influence on the service life of the traction sheave and ropes.

For some years, a 50 percent counterweight balance has in most cases been calculated. This means the torque requirement on the downward trip of the empty car and the upward trip of the full car is equally high. The drives and frequency converters are best calculated this way.

Initially, there are only disadvantages …

Old lifts from the end of the past millennium were often calculated with 45 or 40 percent counterweight balancing. What are the advantages of a lift with 40 percent counterweight balancing?

Initially, there are only disadvantages. The drive, brake, frequency converter, rope and traction sheave have to be calculated for full load. This means these components have to be calculated with a higher torque. For a full-load trip upwards, a lift with 40 percent counterweight balancing requires 25 percent more torque than a lift with 50 percent counterweight balancing.

Why were lifts in the past built with 45 percent or 40 percent counterweight balancing despite this apparent disadvantage? The advantage is in the use of the lift. A lift is seldom used with full-load upwards. However, the car regularly travels downwards unloaded.

The advantages of 40 percent ...

Photo: © Ziehl-Abegg

Photo: © Ziehl-AbeggIf the lift travels downwards unloaded, it only requires 80 percent torque. The proof of traction capacity is easier as a result of the lower differential weight between car and counterweight. The optimal aperture angle of the undercut or V-grooves can be selected. As a result, the surface pressure between traction sheave and rope is lower.

A lift with 40 percent counterweight balancing has the following advantages:

• Approx. 10 – 20 percent energy saving

• Longer service life of rope + traction sheave

• Lower steel consumption, much lower ecological footprint

• Shorter installation time

• Lower material costs

• Old lifts do not require additional loading - in older lifts, the counterweight balancing is almost never correct.

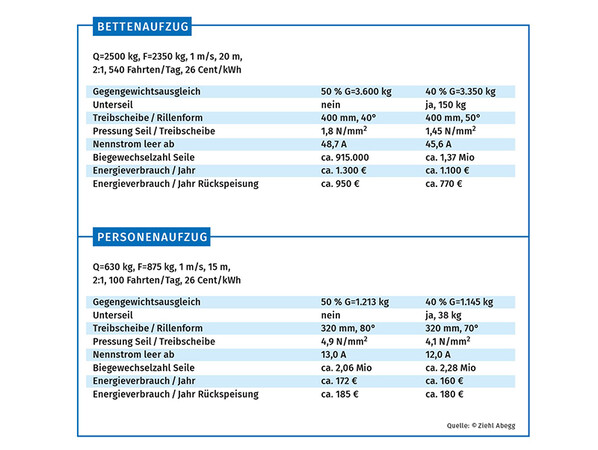

Examples:

The tables show a comparison with 40 percent and 50 percent counterweight balancing. A balance chain has to be installed in a goods lift. The surface pressure between traction sheave and rope is much lower. As a result, the number of bending cycles per rope is higher. Rope and traction sheave have a much higher bending cycle number. The energy consumption in goods lifts is 18 percent lower.

Energy feedback on many trips

The energy consumption in passenger lifts is negligible. The rated current during the downward trip with empty car is lower. When comparing both tables, it is noticeable that the energy consumption depends heavily on the number of trips. Lifts with a lower number of trips consume less energy. But these lifts also recover little energy. Therefore, the use of energy feedback or energy storage only makes sense if the lift makes a lot of trips.

To enable lifts to be built and operated as efficiently as possible, the counterweight balancing should be designed with at least 40 percent. The energy consumption is then much lower. The rope and traction sheave have much less wear and permit a much higher number of trips. Particularly in the event of modernisation, the counterweight usually does not have to undergo expensive additional loading.

The author is the regional sales director (drive technology department) at Ziehl Abegg SE.

More information: ziehl-abegg.de

Write a comment