Smoke monitoring of lift shafts

The connection between smoke extraction systems for energy saving and comprehensive monitoring of the fire alarm system has many advantages – for the environment and the wallet.

There are different areas of application for monitoring lift shafts. Depending on the fire protection concept, the fire brigade must be informed directly via the fire alarm system in the event of smoke in the shaft. Alternatively, the monitoring is used to open the aperture for smoke extraction, which is closed on energy efficiency grounds. If both scenarios are supported, two separate systems are currently often installed, resulting in unnecessary costs during installation and maintenance.

The energy efficiency requirements for lift shafts in Germany were further tightened here by the introduction of the Building Energy Act (GEG) in November 2020. Under the new GEG and accompanying DIN EN ISO 9972, temporary sealing or bonding of the openings in lift shafts is prohibited for the blower door test. The lift shaft may only be closed with a system for smoke extraction and ventilation, which is closed in normal operation and only opens if necessary.

1,000 euro savings

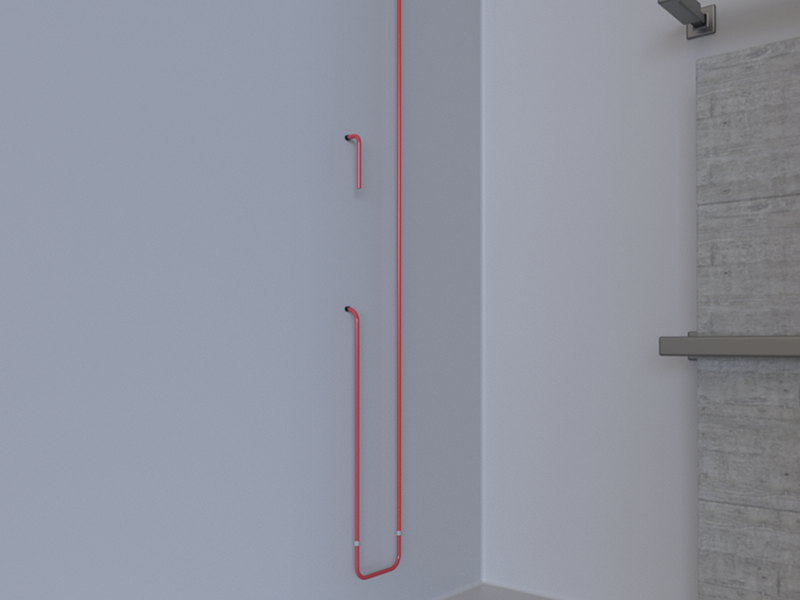

Intake pipe in the shaft: example of the arrangement of the intake pipe in the lift shaft. Photo: © B.A.S.E. Solution GmbH

Intake pipe in the shaft: example of the arrangement of the intake pipe in the lift shaft. Photo: © B.A.S.E. Solution GmbHInstallation of such a system also makes sense ecologically. Operators can save about four tons of CO² and 1,000 euros in heating and environmental costs annually by using this system. These figures could rise even more clearly, depending on building use. The investment will be amortised in most cases within two to five years.

The Federal Ministry for Economic Affairs and Energy currently plans to adopt installation of automatic systems for smoke extraction and ventilation in its list of measures eligible for subsidies. In addition, by retrofitting these systems, the ESG balance sheet can be optimised. ESG refers to taking criteria into account criteria from the fields of the environment, social and governance.

Retrofitting possible

Particularly in the case of existing buildings, systems to save energy are currently very seldom used. There is still great potential here to enhance energy efficiency and as a result boost property value. Retrofitting is possible in almost every lift.

Apart from smoke extraction, the fire alarm system is also obliged to monitor the shaft for smoke if this is required in the fire protection concept. This is always the case if the building is to be comprehensively monitored (category 1, full protection) or the lift shaft is part of the monitoring area of the fire alarm system for other reasons. As far as the lift shaft is concerned, this means the erector or operator of the fire alarm system must include a smoke extraction system for the shaft.

Double monitoring

Smoke enters the shaft: here we show how smoke from the floor penetrates the shaft. Photo: © B.A.S.E. Solution GmbH

Smoke enters the shaft: here we show how smoke from the floor penetrates the shaft. Photo: © B.A.S.E. Solution GmbHAs things stand, the erector of the fire alarm system must install a smoke extraction system for the fire brigade alarm while the erector of the lift installs a closure flap including smoke alarm to save energy in the shaft. Consequently, the lift shaft is doubly monitored.

This duplicated effort can be avoided. Activation of the closure flap for smoke extraction can also be performed by an alarm contact from a coupler on the fire alarm system and does not need any smoke detection of its own. Consequently, the smoke alarm of the lift erector can be eliminated, reducing the additional maintenance effort and legally regulated replacement of smoke alarms.

Installation outside of the shaft

To comply with the normal German standards and guidelines (DIN 14675, VDE 0833-1, VDE 0833-2 as well as the technical connection terms of the fire brigade [TAB]), several important points must be complied with.

The evaluation unit of the smoke extraction alarm must be placed to ensure that it is accessible at all time to fire alarm maintenance companies and the fire brigade. It should therefore be installed outside the lift shaft. Only the intake pipe is installed in the shaft, with the assistance of the lift company. This means maintenance and fault clearance can be performed without incurring the costs for deploying a lift technician.

In new buildings, including planning of the laying of the intake pipe directly with the erector of the lift to eliminate any avoidable interfaces here makes sense. The intake pipe is then laid in the shaft up to the outlet drill holes required and can then be further processed by the erector of the fire alarm system. The erector of the fire alarm system draws up matching project planning for the creation of the intake openings, which is then implemented by the lift company.

Before the fire alarm system is commissioned, the installation of the fire alarm system undergoes an acceptance inspection by the fire alarm erector to enable it to issue a conformity declaration.

Alarm in the event of fire

Smoke moves through the shaft to the outside. Photo: © B.A.S.E. Solution GmbH

Smoke moves through the shaft to the outside. Photo: © B.A.S.E. Solution GmbHThe opening required by building codes in the shaft head for smoke extraction is closed airtight by a suitable closure element. In the event of fire, the alarm is raised when a fire alarm monitors the shaft via a coupler in the shaft head. In addition, the control unit must ensure various ventilation functions.

According to the standards and guidelines in force, the air temperature in the shaft has to be measured and kept below 40° C. Most systems open at a temperature of 30° C to enable the hot air to escape and avoid any heat accumulation. In addition, in the event of a lift malfunction, ventilation of the car must be ensured.

No natural exchange of air can occur if the car is not in motion. This can only occur if the air in the shaft is in motion. To achieve this, the potential-free malfunction signals are connected to the systems for smoke extraction and ventilation to enable the closure flap to open and air to move through the shaft.

Conclusion

Irrespective of whether the fire alarm system can be expanded or the shaft is to be sealed on energy efficiency grounds, both considerations can be combined given thorough planning. The environment is conserved, heating and environmental costs are reduced and the construction period or costs of the installation are minimised.

By Lars Walter-Sinsel

The author is the managing director of the B.A.S.E. Gebäudetechnik GmbH

More information: www.base-gebaeudetechnik.de

Write a comment