Lift operators throwing money out the window

Every year in Germany alone, lifts are responsible for up to 500 million euros in avoidable energy costs. Lift operators are literally throwing money out the window.

The reason for this is the permanently attached opening for the legally prescribed ventilation and smoke extraction of the lift shaft, which to this day is still to be found in most lifts. As a result, lift operators are literally throwing money out the window.

According to the calculations of the Central Association of the Electrical Engineering and Electronics Industry, an average lift shaft of 19 m in height with six landings as a result causes avoidable energy costs of about 1,000 euros annually through the permanently open smoke extraction area.

Sealed external envelopes, as called for by the Energy Savings Ordinance (EnEV) or buildings according to the passive building standard cannot be reconciled with a permanently opened smoke extraction opening at all.

Automatic lift smoke extraction systems

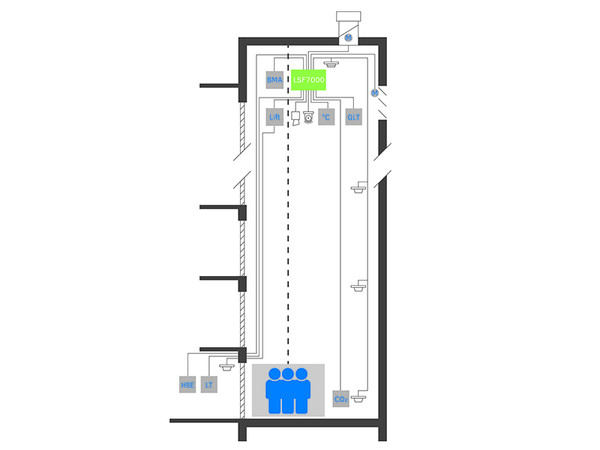

An optimal solution that reconciles fire protection, ventilation and the requirements of the EnEV are automatic lift smoke extraction systems (ASE), which are also suitable for controlled ventilation (cf. Fig.1).

Fig. 1: Diagram of a lift shaft smoke extraction system. Photo: © Aumüller Aumatic GmbH

Fig. 1: Diagram of a lift shaft smoke extraction system. Photo: © Aumüller Aumatic GmbHIn normal operation, the smoke extraction opening is closed to ensure no heat is lost. If the system identifies smoke in the lift shaft, an electric drive opens the shaft head to ensure toxic gases and smoke can escape. The opening in the shaft head for ventilation is also opened automatically in the event of deterioration of the air quality in the lift shaft in suitable systems.

The structure of a lift shaft smoke extraction system consists of a controller, sensors for fire or smoke detection and to measure the air quality as well as electrically operated roof or facade elements to open the shaft head. Reliable smoke detection

Smoke detection in the lift shaft can also be realised by an aspirating smoke detector and by point or linear smoke detectors. Point detectors are found mainly in flats and smaller lift shafts while linear smoke detectors also monitor large distances. Systems that are suitable and licensed for this also cover the use of an existing fire alarm system for detecting fire in the lift shaft.

Ventilation of lifts

Adequate ventilation of the lift shaft is equally important. In normal operation, air exchange is as a rule guaranteed by the ventilation openings in the car. If the car comes to a standstill as a result of a malfunction or in the event of maintenance, the air exchange has to be secured by an opening in the shaft. Measurements have shown that health-threatening CO2 concentrations are already reached within a few minutes of a standstill in the car.

In this case, a lift shaft smoke extraction system automatically opens the roof or façade elements. If temperature, air quality or CO2 in values are exceeded, controlled natural ventilation is also possible as an option via sensors in suitable systems.

Opening the shaft head

Fig. 2: A roof hood with closing element for weather-dependent smoke extraction. Photo: © Chris Müller Photodesign

Fig. 2: A roof hood with closing element for weather-dependent smoke extraction. Photo: © Chris Müller PhotodesignNatural smoke and heat extraction devices guarantee reliable actuation of smoke extraction or ventilation opening, which if used in roof hoods have to be certified for horizontal use. Light domes without a wind and rain-dependent control are not suitable. Consequently, slat elements with integrated closing element and weather protection are normally used (cf. Fig. 2).

The patent EP 1890956 has been applied for in connection with the ventilation of lifts. Operators should clarify with the manufacturer of the lift shaft smoke extraction system whether patent use exists or whether the payment of licence fees is incurred.

Ramona Meinzer is the chair of the management board at Aumüller Aumatic GmbH, a manufacturer of system components for the automation of windows for controlled natural ventilation and smoke and heat extraction.

More information:aumueller-gmbh.de

Write a comment