Inter alia, the chairman of CEN/TC 10 explained what consequences the megatrends of the coming years would have for the lift and escalator sector.

With your international experience, how do you see the development and megatrends of the coming years in the lift and escalator industry?

Gharibaan: There are several megatrends which affect our industry in different ways. Urbanization is one of the obvious ones. Currently 55% of world population lives in the cities, this will increase to 68% by 2050. In combination with population growth, this will result in adding another 2.5 billion people to the current population in urban areas. For economic as well as sustainability reasons, most people will live in multi-storey buildings. Adding services such as shopping centres and transport hubs to support the communities will fuel growth for the lift industry globally. Of course, the rate of urbanization varies for each region of the world, thus the effect will be felt differently in different markets.

Another important trend is sustainability. The lift industry has been focusing on energy efficiency for some time now and we have seen considerable improvement in energy performance in modern lifts compared to the same type of lift just a decade ago. But other environmental matters such as material consumption or recycling may also become just as important. In addition, other aspects of sustainability related to social responsibilities also need to be considered. One good example is accessibility, which may greatly improve the quality of life for many citizens and facilitate care for older people in their own homes rather than moving them to other facilities.

Digitalization is rather a new trend for the lift industry. For example, connectivity for lifts, which was a luxurious option just a while ago, has become commonplace and gradually a necessity. Digitalization may provide many benefits for all stakeholders in the form of improved services, etc. but it also presents challenges such as cybersecurity. Safety of course remains absolutely important for the lift industry and for all stakeholders.

In view of these developments, where do you see your task as CEN/TC 10 Chair today and in the future?

Gharibaan: First of all, we need to make sure that our standardization work is aligned with and reflects the needs of European countries. European standards are adopted by the CEN member countries as their national standards. Therefore, it is extremely important to make sure that national needs and requirements are presented and adequately considered during the development of the standards. Of course, CEN processes are established to achieve this, but our technical committee also plays an important role in following and enforcing the relevant procedures.

European standardization for lifts and escalators has had an impact in improving safety and accessibility for passengers and workers. Standardization also has an impact on the competitiveness and innovativeness for the European industry, benefiting all stakeholders. We need to ensure the continuity of the standardization work and adjust to the changes in technologies, regulatory framework and needs of stakeholders. CEN/TC 10, through ballots or meetings regularly consults its members to ensure the alignment of its work with the needs of the members.

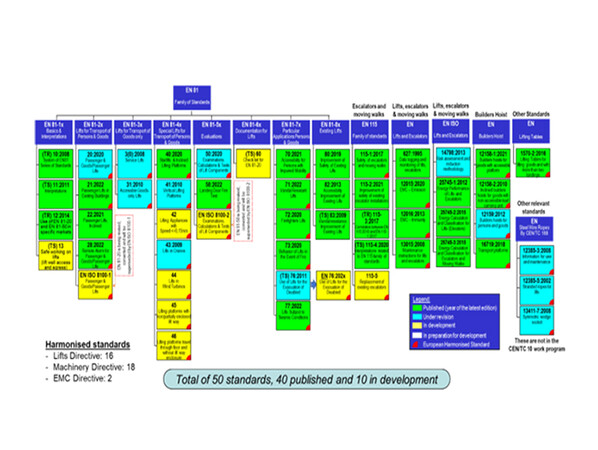

The current work program of CEN/TC 10. Photo: © CEN/TC 10

The current work program of CEN/TC 10. Photo: © CEN/TC 10Many of our standards are European harmonized standards in support of EU legislation. By working very closely with the EU Commission and CEN services, we must ensure that our standards are fully aligned with the conditions set by the EU Commission and maintain the harmonization status of those standards.

Standardization work is carried out by the voluntary participation of experts from interested parties and stakeholders. We need to encourage and facilitate participation of those experts, especially by SMEs, in the national and/or international committees and working groups. Shortage of adequate expert resources might be the main risk for the future of standardization. CEN/TC 10 is open to and welcomes experts from all stakeholders. We are also adjusting our work program and extending our international cooperation, e.g. with ISO, to make sure that the available resources are deployed efficiently and effectively.

Another important point is to consider the international dimension of European standards. European standards for lifts and escalators are used in many countries outside Europe. For example, EN 81-20 for lifts and EN 115-1 for escalators are the basis for national standards in many countries around the world.

Urbanization, or rather difference in the regional rate of urbanization, has had a profound impact on the structure of the lift industry. For example, extremely high rate of urbanization in China and Asia Pacific has raised the local and regional demand for lifts and escalators considerably. Naturally, the industry has set up manufacturing facilities and distribution centres to serve those markets.

Well-developed and maintained European standards help to set a common level of safety for lifts and escalators wherever this equipment is installed. Use of those standards also greatly helps to harmonise the technical requirements for lifts and escalators among countries by adopting the same requirement in every country through the standardization process.

Technical harmonization has many benefits for all stakeholders. For example, it can reduce costs across the delivery chain due to economies of scale, flexibility in sourcing as the components purchased from different countries fulfil the same requirements, reduction in certification time (thus reducing time from design to the market) and many more benefits.

From the standardization process point of view, it is becoming very important for all standardization committees and working groups to make sure that the needs, inputs and views from all users of the standards are adequately considered. To achieve this, CEN and CEN/TC 10 have established several cooperation agreements and forums to engage non-European users of the standards. With all the changes going on around us, international cooperation is also a critical factor in maintaining the relevance of European standards on the world stage.

Which new standards can be expected soon? Will they bring important technical changes for the industry?

Gharibaan: A complete overview of CEN/TC 10 work program is given in Figure 1. We have several new standards. EN 81-42 is a standard which covers lifting appliances with fully enclosed carrier. You may be familiar with EN 81-41 which covers lifting platforms. The difference here is that the carrier (car) in EN 81-42 is fully enclosed with car doors, etc., like lifts under EN 81-20. But the speed is limited to 0:15 m/s, which means that this standard will be harmonized under the Machinery Directive. We expect EN 81-42 to be published by the end of 2023.

EN 81-76 is a new standard for evacuation of buildings using lifts. This standard was a Technical Specification (CEN/TS 81-76), but it is now being completely revised. We expect the publication to be early 2024. Another standard is EN 115-5 for replacing escalators in existing buildings. This should also be available during 2024. ISO 8102-20 for cybersecurity of lifts and escalators is another very important standard, which is being developed by ISO. We expect it to be published during this year. As new standards, we can expect that these will have a big influence on design and installation of lifts and escalators.

Why do we actually need so many lift standards? This is a big challenge for medium-sized companies...

Gharibaan: There are many reasons for having standards. For example, to establish specifications, which provide common level safety or accessibility regardless of the manufacture.

Using standards, such as European harmonized standards, to comply with the regulations is another important reason. Using harmonized standards may considerably reduce the costs of certification, especially for small and medium-sized enterprises (SMEs).

Photo: © Ulrike Lotze

Photo: © Ulrike LotzeAnother question might be to ask if it would not be better to put everything in one standard instead of having separate standards for different topics. The structure of the CEN/TC 10 series of standards is modular. This means that there is a main safety standard, e.g., EN 81-20, and other specific topics are covered by separate standards, for example EN 81-72 for firefighter lifts. This structure has many advantages – for example, not all lifts are firefighter lifts. Therefore, a separate standard clearly defines what is needed for firefighter lifts without complicating the main safety standard, which applies to all lifts.

Changes of technology, innovations and user experience requires regular updates/revisions of our standards. Having separate standard for each topic makes revising only the standard by those changes easier. For example, if the technology for tele-alarm is changed, we update the EN 81-28 and we do not need to revise the main safety standard (EN 81-20) for lifts. This not only simplifies and shortens the time for revision of the standard, but also helps the user of the standard to identify only the changes to that aspect of the lift and not to be concerned about the main safety standard.

Imagine if everything was in one standard, e.g., EN 81-20.Any time something changed, we would have to revise the main standard. This is a time-consuming process and could also be very difficult for the users, especially for SMEs to purchase the revised main standard (relatively expensive due to its size) and also to apply it, including possible re-certification, etc.

As mentioned, European standards are used by many countries around the world. There is a general consensus on the requirements for safety of the lifts and escalators among those countries. But issues such as fire protection or accessibility differ greatly from one country to another. If everything is put into one standard, it would be impossible to get consensus on using that standard in all those countries. This would greatly harm the technical harmonization we have achieved with much effort by all stakeholders.

There are around 20 million existing lifts and escalators worldwide. Every year, about one million new units are added. Many new EN/ISO standards are being developed for new installations. Why not also deal with standards and regulations for the many existing installations? After all, this is about increasing safety, energy efficiency, accessibility, environment, cyber security, digitalization, sustainability, etc.

Gharibaan: Existing equipment (equipment in operation) is the focus of CEN/TC 10. We have made several standards to improve safety and accessibility for this equipment. Examples are EN 81-80, EN 81-82 and EN 81-83 for lifts as well as EN 115-2 for escalators. There are several challenges for further standardization. For example, the requirements for existing equipment are governed by national regulations that differ in each country, even in the EU. Therefore, achieving consensus on the requirements of the standards which also fulfils those different national regulations is very hard to achieve.

In addition, application of the standards for existing equipment is on a voluntary basis or needs a national regulation to enforce the standards. Therefore, except for EN 81-80, which has been referenced by national regulations in many EU countries, there is no such enforcement for other standards. Nevertheless, CEN/TC 10 continues upgrading the current standards and will initiate new standards whenever feasible.

How do you see the role of SMEs and the component industry in the standards and regulations of the lift industry?

Gharibaan: SMEs and the component industry play a crucial role in standardization. To my understanding, they are the main users and beneficiaries of the standards. This is true especially for the European harmonized standards, where their application reduces the conformity assessment and certification costs considerably. To my knowledge, SME experts are also highly competent and have wide experience as they are exposed to many aspects of their company business.

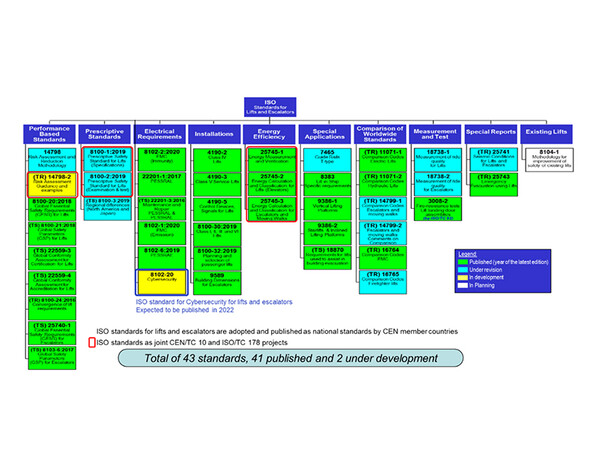

The current work program of ISO/TC 178. Photo: © ISO/TC 178

The current work program of ISO/TC 178. Photo: © ISO/TC 178My wish is to have wider participation and contribution from SME experts. I also understand the resource and financial constraints of the SMEs. I can only encourage SME experts to join the standardization work. If their limitation in resources does not allow participation at the international level, they should at least try to join their national standardization body (NSB) committees and working groups. NSBs play a crucial role in the international standardization organizations, such as CEN and ISO. NSBs decide (vote) on which standards are to be developed. They also provide comments on draft standards and at the end they approve the standard.

I am strongly convinced that participation in NSBs will provide immediate benefit as the participants get the information much in advance of the publication of the standards and they could align their product and services in a timely, orderly and cost-effective manner.

The new regulation on machinery products is coming, which will replace the Machinery Directive. What are the main issues facing the industry here and when?

Gharibaan: The first important change is that the Machinery Directive will become the Machinery Regulation. EU regulations do not need any national transposition; therefore the requirements are more transparent and applied consistently and at the same time in all EU Member States. From the Essential Health and Safety Requirements (EHSRs) point of view, the new Machinery Regulation will also address risks due to the use of software and artificial intelligence in safety functions. Besides, issues such as cybersecurity might become an important aspect to consider. The regulation allows product documentation to be provided in digital format.

The regulation is still in the approval process, and we still need to wait to see the final text and requirements before a more detailed impact analysis can be made. The new regulation will have consequences for standardization and certificates. But again, to evaluate the impact, we need to get the final text as well as the content of the new standardization request to be issued by the EU Commission. This is a very important regulation as it will affect lifts, escalators and lifting appliances, basically all the products for the lift industry. It is important to analyse the content as soon as the final text is available.

You are in close exchange with the EU and the HAS-consultants – are the next harmonization steps foreseeable?

Gharibaan: Due to the EU Court of Justice decision in 2016 that EU Harmonized standards are a part of EU laws, the EU Commission has set specific criteria for acceptance and citation of the references of the harmonized standards in the Official Journal EU (OJEU). The citation gives the harmonized standard status of "providing presumption of conformity" to the requirement of the relevant EU Directives or regulations. Without this citation, the harmonized standard has the same status as any other non-harmonized European standard. We have been working very closely with the EU Commission, Harmonized standard (HAS) Consultants and CEN services to clarify and agree on those criteria for harmonized standards for lifts. We have been applying those agreements based on a roadmap agreed with the EU Commission.

Photo: © Ulrike Lotze

Photo: © Ulrike LotzeThis cooperation has been very successful and as a result the references of EN 81-20/50:2020 as well as EN 81-72:2020 and EN 81-73:2020 have been published in the OJEU. We expect the references of EN 81-21, 28, 58, 70, 71 and 77, which are published in 2022, to be cited in the OJEU during this year. Therefore, I am confident that we will have our standards cited and maintain their status as the European harmonized standards.

What do you advise the manufacturers: to bring new products to the market according to the harmonized (technically often no longer up to date) standards – with the risk of possibly repeating the process?

Gharibaan: The answer to this question depends on many factors, which might be different for each individual manufacturer. In general, manufacturers should evaluate their products, conformity assessment modules that they have applied, the expiry date of the certificates and other relevant factors and decide how to reference the new standards for their products and documents. What I can say is that in the revision of our standard to align them with the new citation criteria, we (CEN/TC 10) have been very careful not to make any technical changes. Therefore, the newly published version of the standards is technically the same as the older version.

What is the actual timetable for the transition of EN 81-20/50 into EN ISO 8100-1/2?

Gharibaan: EN ISO 8100-1/2 is a joint project between CEN/TC 10 and ISO/TC 178. The objective is to revise EN 81-20/50:2020 and ISO 8100-1/2:2019 (currently identical to EN 81-20/50:2014) and bring the result into one set of global standards (EN) ISO 8100-1/2.

(EN) ISO 8100-1/2 is expected to be published in the first quarter of 2025. It will be known globally as ISO 8100-1/2:2025 and in Europe it will be known as EN ISO 8100-1/2:2025. EN ISO 8100-1/2:2025 will be a European harmonized standard and consequently EN 81-20/50:2020 will be withdrawn at the latest by the first quarter of 2028, a maximum of three years after publication of EN ISO 8100-1/2:2025. The exact date of withdrawal will be decided by the CEN/TC 10 members in a ballot.

What is the significance of non-harmonized ISO standards for the market and manufacturers?

Gharibaan: ISO/TC 178 has a comprehensive set of standards (see figure 2 for details). Several of those standards have also become European standards. For example, EN ISO 14798 for risk assessment or EN ISO 25745/1/2/3 for energy efficiency measurement and classification. These EN ISO standards are good examples of international cooperation and efficient use of our expert resources, i.e., one standard in ISO and CEN at the same time.

There are also other ISO standards that might be of great importance or interest which have not (yet) been adopted as European standards. A good example is ISO 8102-20 for cybersecurity, which will be published soon. Another example is ISO 8100-32 for planning and selection of lifts in buildings. I would strongly suggest to all to familiarize themselves with the ISO standards. Those standards might be useful for their products and services.

The interview was held by Ulrike Lotze

More information: Esfandiar Gharibaan is the Chairman of CEN/TC 10, the Technical Committee in the European Committee for Standardization (CEN), responsible for developing and maintaining European standards for lifts, escalators and moving walks. He is also a member of several CEN and ISO standardization committees and working groups for lifts and escalators.

He received his Master of Science (MSc.) degree in CAD/CAM and Robotics from Middlesex University in London, United Kingdom and worked in the field of mechanical engineering in the UK and Canada for several years.

He joined KONE Corporation in 1988 and held various management positions in engineering, R&D and business process development in several countries. Currently, he is the Vice President responsible for worldwide Codes and Standards in KONE Corporation.

Write a comment