Steel shaft challenge

Existing buildings can usually only be converted to barrier-free buildings through lift shafts installed in the stairwell or courtyard. What counts is that the lift manufacturer is familiar with the challenges associated with a steel shaft.

By Stephan Zülch

Residential space in Germany is scarce and expensive. The cities are overdeveloped with many existing buildings undergoing renovation. In 2021, more than a fifth (20.8 percent) of the EU population was 65 and older. The older people become, the more important the subject of barrier freedom and lifts becomes. A steel shaft is advisable in existing buildings, since it is easier and faster to implement than a concrete shaft.

For steel shafts, lift manufacturers must turn to suppliers who deal with such matters on a daily basis and who can make adjustments for the different lift versions. It is crucial that all of the technical construction elements needed are available to the lift builder in the steel shaft. The steel shaft manufacturer must clarify and plan a number of things in advance.

Technology and appearance

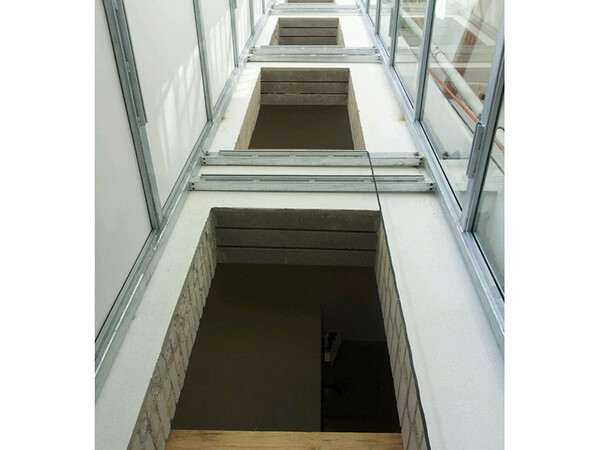

Photo: © Stephan Zülch / Schlosserei Schiemann

Photo: © Stephan Zülch / Schlosserei Schiemann• Coordination with the lift manufacturer on the interior design for the mounting of technical elements and later to be installed car

• Coordinate whether the shaft has to be air conditioned or heated

• Coordinate what the shaft head and wall connection should look like

• Coordinate whether the roof structure of the building has to be altered

• Coordinate whether external panel or glass shaft cladding is needed

• Coordinate and measure the pit needed.

Logistics, transport and mounting conditions

• Obstacles regarding access to the installation location must be detected and taken into account

• To raise external shafts over a building in the inner city, a crane truck is required if the parts are not to be flown in

• Overhead lines for buses and trams can be a problem for the crane position The road may have to be closed or shutting off the power for the overhead transport company lines may be necessary here

• Trees in the inner city can also create problems for the crane position. Closing the road, truncation or transplantation may be needed

• Channels or cavities and underground garage entrances, etc. must be able to withstand the weight of a crane and its load. Special solutions may have to be created if necessary to guarantee the stability of the crane truck

• Every external shaft lift requires a corresponding foundation or pit. Since this foundation / pit has to be installed in the earth, the quality of the ground has to be taken into account. These foundations have to be installed on the undisturbed ground to provide sufficient stability

• Fire protection issues have to be taken into account – e.g. if the shaft is directly next to the kitchen window (subject: fire spread)

Attachment to the façade or stairwell

Photo: © Stephan Zülch / Schlosserei Schiemann

Photo: © Stephan Zülch / Schlosserei SchiemannThere are many versions and challenges that face the steel lift or shaft manufacturer and which it must have a command of.

• It must specify the connection to the façade and the statics of the connection must be calculated.

• The shaft head often projects into the roof area – the gutters and pantile then have to be dismantled.

• The steel shaft may have to be attached to a balcony.

• There are requirements for protected buildings that have to be included in the design.

• Consultation with the architects/planners regarding access to the lift - for example, if structures outside the shaft become necessary for access to the lift, since direct access to the lift from the building is not possible.

Conclusion

The subject of lifts in connection with existing buildings and residential quality is already important and will become even more important in future. Steel shafts for retrofitting with lifts have been the go-to solution for many years, but their installation requires a great deal of specialist know-how.

The author is the managing director of the metalworking company Schiemann.

More information: schiemann-langenfeld.de

Write a comment